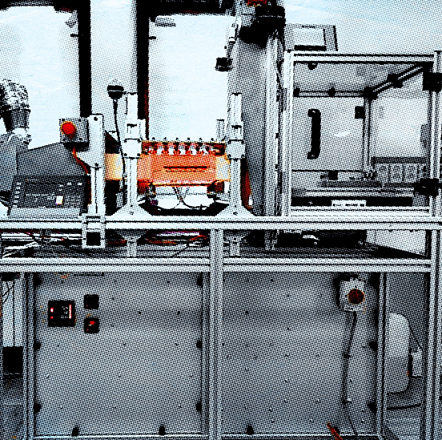

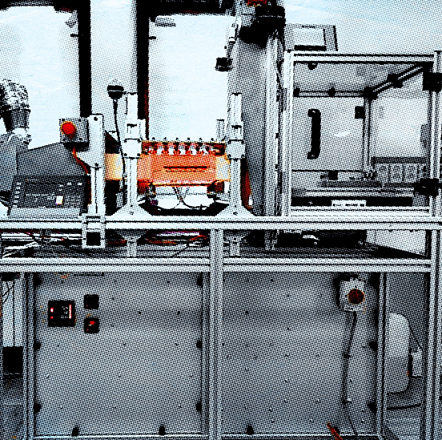

RTP Reactor with Full Wafer TGA Capabilities

Perform Thermogravimetric Analysis (TGA) while drying your printed pastes and then fire in the same process chamber. Know what goes on with your metallization processes without tying up volume manufacturing equipment.

Configurable to your needs:

If you only need an R&D firing reactor, omit the weighing capability. If you are not going to fire with your solar TGA, specify smaller lamp modules.

Macro TGA can be extended to other applications such as lacquers and veneers, as well as other belt oven processes.

Key features:

• Four zones lamp heated process chamber with laminar flow capabilities and solvent exhaust

• Programmable PLC based recipe structure with open – and closed - loop temperature control

• PID tuning separately in each recipe step, allowing the simulation of any industrial belt oven/furnace

• Advanced linearization to accurately match DATAPAQ™ temperature readings

• Process temperatures > 1000°C

• Temperatures ramp up rates > 250°C/sec

• Wafer susceptor counter balance arm with jewel bearings

• Precision scale module with 0.1 mg readability actuated by the counter balance arm

• PLC based programmable temperature and weight data acquisition

• Raw data storage on SD card or user’s PC; data is exportable as .csv file for evaluation

• Emergency stop circuits integrated to manual buttons limit controllers

• Manual wafer loader

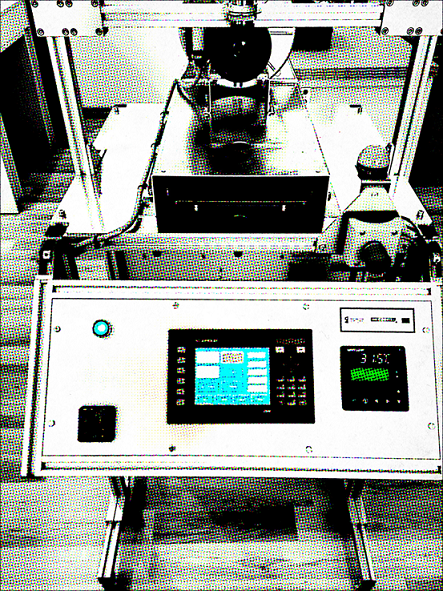

Full Wafer DSC Measurement Equipment

Perform Differential Scanning Calorimetry (DSC) while you dry your printed pastes. Know what goes on with your metallization processes without tying up volume manufacturing equipment.

Configurable to your needs:

If you only need an R&D paste dryer, omit the paste IR measurement capability.

Macro DSC can be extended to other applications such as lacquers and veneers, as well as other planar belt oven processes.

Key features:

• Single zone 3 phase bottom lamp heated process chamber with controllable solvent exhaust blower

• Programmable structure with open – and closed - loop temperature control

• Process temperatures > 400°C

• Pedestal temperature ramp up rates > 35°C/sec

• Titanium wafer pedestal with TC temperature measurement

• Precision short wave digital IR sensor for object temperature measurements

• PLC based programmable dual temperature acquisition

• Raw data storage on SD card or user’s PC; data is exportable as .csv file for evaluation

• Emergency stop circuits integrated to manual buttons limit controllers

• Manual wafer loader

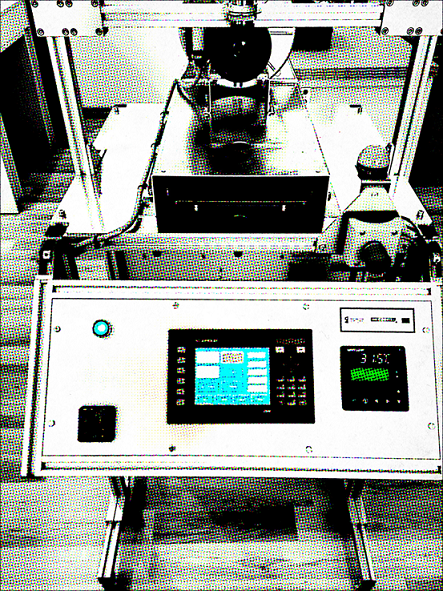

4-Points Transition Measurement Equipment

Bare bone contact resistance measurements. Bring your own precision Digital Volt Meter and the Current Loop Calibrator without breaking the bank.

Key features:

• 10 probe tips in 2 rows of 5 allowing to measure consecutively between 1 reference finger and 4 other fingers

• Configurable probe distance to allow the measurement over a band of finger distances

• Manual mechanical probe tip with 2 axis motions

• Manual wafer positioning

• PLC controlled probe selection with manual back up option

• 156mm x 156mm (or customized size) wafer pedestal

• 230V 50Hz single-phase power inlet

• Pedestal heating function up to 180°C

• PLC controlled heater with stepwise incremental temperature

• Electronic limit controller independent from PLC controller

• Emergency heater power off switch (EMS switch)

• 4mm banana Connections for external current source and voltmeter

• Test leads for current source and voltmeter

• Current source and Voltmeter not included (optional at additional charge)

For quote please contact our Sales representatives:

Poland: biuro@thermolytix.eu

Rest of World: sales@thermolytix.eu